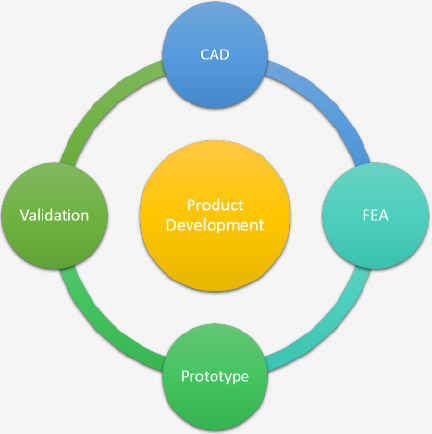

Anand NVH is a design capable supplier having dedicated CAD & FEA Teams located in USA, Germany & India having capability of Linear, Non Linear analysis & Durablity Prediction capabilities. Dedicated Research and Testing Capabilities are available at Techncial centers in India & USA.

The company has invested in a new 15,000 Sq Ft Technical centre at the Gurugram faclity which is equipped with Multi Axis Durablity Test bench With Real Time Load Data (RLD) Processor.

Our Technical Centre has recieved recognition by Govt. of India. The design capablities are fulfilled with the use of advanced software like Abaqus, Hypermesh, Creo Parametric (Pro 6), Auto CAD, Fe Safe, Catia V5 6R 2016.

TECHNICAL CENTRES

-

Anand NVH Products , INC

Anand NVH Products , INC 39555 Orchard Hill Place Suite 115 Novi, MI 48375 USA

-

Anand NVH Products (P) Ltd

Plot No. 33, Sector -35 HSIIDC, Gurugram Haryana -122001, INDIA

-

Anand NVH Products GmbH

Gewerbepark 18 49143 Bissendorf Germany

Design Capabilities

Design tools

Abaqus

-

3D Model Package

Creo Parametric 3.0 -

2D Model Package

Autocad 2016

FEA Software

Finite Elements

Abaqus

Structural Components, Brackets & Bracket Assemblies etc.

- Linear Analysis

- Modal Analysis

- Non-Linear analysis of high load conditions

- Durability

Elastomer Analysis

- Static Simulation

- Elastic center calculation

- Fe Safe/ Rubber Fatigue Failure Analysis.

Hypermesh Pre Processing

Laboratory / Testing

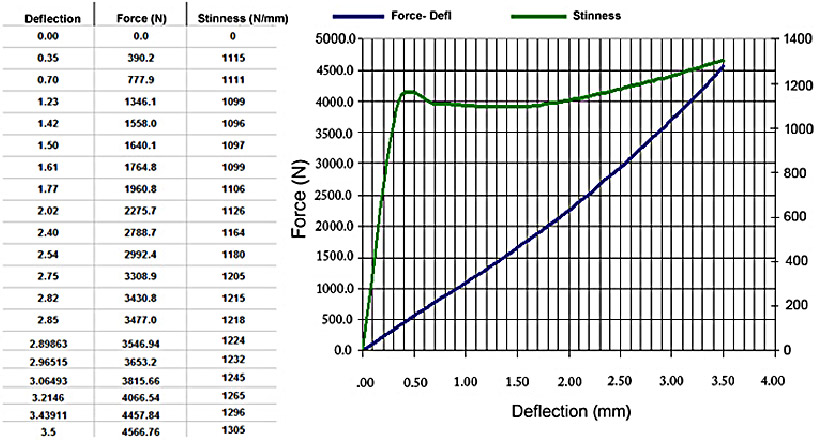

Anand NVH has in-house facilities for rubber compounding, metal preparation, moulding, testing and validation of Products under a single roof. This translates to better control over production and consistent product quality. In 2017, the company has established a greenfield technical centre in Gurugram, India at a cost of 3 Million USD having complete facility for characterization & validation of parts under real load conditions.

The Testing Equipment at Anand NVH are:

- Servo Hydraulic Dynamic testing Machine - Zwick Roell Germany

- UTM for testing Compression & Tension Properties -Model Z100 Zwick Roell, Germany

- Tensile Testing Machine with Extensometer

- Oscillating Disc Rheo Meter

- Mooney Visco Meter

- Torsional and Conical Endurance testing Machine

- Ultra Low Temp. Cabinet with temperature up to minus 70° C

- Hot Air Ageing Oven with temperature up to 300° C

- Salt Spray Chamber

- 3-Axis Bedplate for Tri axial Endurance testing

- 2-Axis Bedplate for Bi axial Endurance testing

- 1-Axis Bedplate for Single axis Endurance testing

- 2-Axis bushing durability for torsional and conical tests with temperature chamber

- Dispersion Analyzer from Alpha Technologies