The manufacturing facility in Imlay City, Michigan was founded in 1985 and covers an area of 145, 000 sq. ft.

This Facility was acquired in the year 2016 and renamed it Anand NVH North America. Moulding, Mould Design/fabrication machine Design & Quality Control are all conducted in house.

Dedicated

110,000 sq.ft

Rubber Moulding & Assembly Area

Dedicated

35,000 sq.ft

Machining & Turning facility

Spread over

145,000 sq.ft

Area

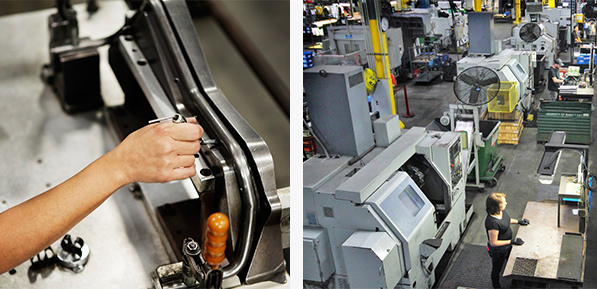

Machining facility

ANP North America has latest state-of-the-art CNC machining with orbital forming and tube bending machines sourced from the makers such as Toyoda, Mori Seki, NTC, Emco, Haas, TA System and Takahashi.

The orbital machine can form collar form tubes with thickness upto 10 mm. The facility has fully automatic length check machine for straight tubes. These machines thus enable some of the best-quality automotive NVH parts USA has.

ANP North America also produces high precision metal components produced from Seamless tubing, Welded tubing and Wrapped construction.

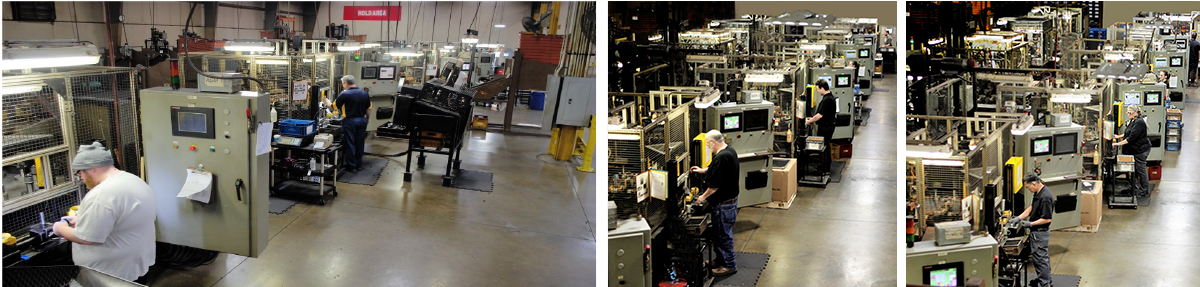

Moulding facility

ANP North America has latest state-of-the-art Molding facilities for all types of rubber compounds including silicone rubber. The facility is equipped with moulding machines ranging from 90 - 800 Tons. The machines have been sourced from the makers such as LWB, Dieffenbacher and Maplan.

Assembly Facility

ANP North America has latest state-of-the-art assembly and in-line inspection equipment. It is in complete compliance with the standards of automotive NVH parts USA expects from its best companies. Major types of machines installed in the assembly area include rotary swedging and inspection, ferrule assembly and glue assembly among others. The company always places major emphasis on Precision and Superb quality of the end Products. The facility is highly skilled and experienced in machine design and fabrication which is shared with other ANP facilities.

Tool Room

A significant bulk of automotive NVH parts USA produces today are manufactured at Anand NVH North America. That's because we have the advantage of being a self-sufficient entity which has its own inhouse tooling facility which manufacture all sort of tools & Molds. We also do all over Internal retooling and repairs to reduce Potential downtime.

The tool room is equipped with latest Vertical Milling Centers and EDMs. For testing of moulds, it has advanced setup of profile projectors, 3D CMM, Metallurgical Microscopes and Roughness testers.